Shanghai Jiechuang Mold Manufacturing Co.,Ltd. is located in the

Songjiang District of Shanghai city which is so historical that it

was named “the Root of Shanghai”. With only 30-minute distance from

Hongqiao Airport, the traffic here is very convenient. Set up in

2015, Jiechuang now possesses 1 million registered fund and more

than 5 million actual investment. Its team and major engineers all

have worked in rotational moulding industry for more than 10 years,

which makes Jiechuang a modern economic entity that concentrates on

technological research, design development ,manufacturing, trade

and investment.

Bearing in mind that Innovation is the driving force of

development, and technology is soul of Creation, workers in

Jiechuang always stick to the path of technological creation in

order to make sure that Jiechuang is the leading rotational molding

manufacturer. In addition, Jiechuang has introduced from home and

abroad large-scale and high-end CNC machines, universal milling

machines, digital controlled lathe, EDM machines, linear cutting

machines, auto-shuttering machines and a dozen of big scale

production equipment . By introducing those advanced manufacturing

equipment, Jiechuang has become the leader of hardware. It has also

joined in Rotomoulding Professional Committee of China and Plastic

Association of China in succession, which wons the company a good

social contact and public praise in rotational molding industry and

further makes it a potential and qualified supplier. Engineers and

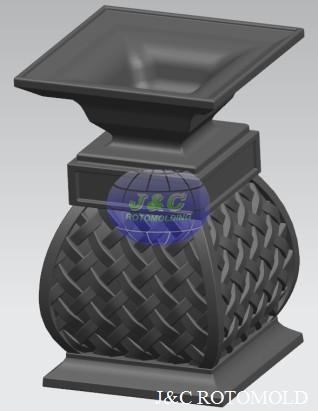

workers here are all elites who have years of experience in floor

cleaning machines, outdoor and indoor playground equipment, kayaks

and surf-boats, furniture, case and gardening planters.

As quality is the lifeblood of enterprise development, Jiechuang

always adheres to the concept of “No quality, No development”and

determines to control quality at the source in order to build the

idea of Total Quality Management (TQM). With rigorous management

system , advanced production technique, and customer-focused

service concept, Jiechuang has set up a strict quality standard so

as to provide customers with constantly improved quality. Jiechuang

has now won a good reputation in both domestic and foreign

countries and the molds and products it produced have been exported

to countries such as America, England, Germany, South Korea, Japan,

Australia, Turkey ,Russia and Ukraine.

Jiechuang sincerely welcome the new and old customers to visit and

cooperate with us! Thanks!